Stellantis On A Quest To Halve Battery Weight In Pursuit Of Lighter EVs

The group plans to plug the weight gap between gas cars and EVs with new battery chemistries.

Stellantis is aiming to halve the battery weight in its future EVs to make them comparable with gas-powered cars, as per a new report. To attain its objective, the group is working with several battery technology companies, exploring suitable chemistries.

At the inauguration of its new Mirafiori Battery Technology Center in Turin, Italy, the group’s engineering boss Ned Curic told Autocar that today’s batteries were too heavy and that lightweight batteries and efficient cell packaging are vital moving forward.

Current lithium-ion batteries are among the heaviest components in EVs, and the heft can adversely affect performance, efficiency, and safety. For instance, a GMC Hummer EV’s battery alone weighs 2,818 pounds, the equivalent of a Honda Civic.

Earlier in 2023, Stellantis invested in California battery company Lyten, which is developing lightweight lithium-sulfur batteries. The San Jose-based company claims a lower material cost, a 60 percent weight reduction, and resistance to thermal runaway.

It has also mentioned the elimination of nickel, manganese, cobalt, and graphite. Cobalt has well-documented negative human and environmental impacts, and several companies are moving away from it.

Stellantis also mentioned sodium-ion batteries as a possible alternative. CATL has developed a first-generation sodium-ion battery and claims a high energy density, fast charging capability, and improved thermal stability. Chinese state-owned carmaker Chery is reportedly the first automaker to use CATL’s sodium-ion (Na-ion) batteries.

Stellantis, which is the parent company of brands like Alfa Romeo, Ram Trucks, Citroen, Peugeot, Jeep, Dodge, Chrysler, and Fiat among others, inaugurated its new $43 million Battery Technology in Turin last week.

With a footprint of 8,000 square meters, the group claims it is one of Europe’s largest battery testing and development hubs. Workers at the facility will oversee stress tests, durability tests, battery management system software development and calibration, and teardowns among other responsibilities.

The group is also working with France’s National Centre For Scientific Research (CNRS) and TotalEnergies-owned battery solutions company Saft to develop a battery that integrates inverter and charger functions within the module to free up space, reduce cost, and improve range. The apparent solution is called Intelligent Battery Integrated System (IBIS), and Stellantis has filed several patents for it.

There are myriad experiments underway in battery technology across the globe with the common goal of reducing costs, improving energy density, and increasing driving range. We’ll have to wait for a few years to see if one or more solutions can solve the persistent issue of range anxiety.

Nissan Aims To Be ‘In The Top Group’ With Cheaper, Better All-Solid-State Batteries

Solid-state batteries are coming to a Nissan product by 2028, and look to offer great power density, charging time, and price.

Nissan swarmed the opening day of the Japan Mobility Show in Tokyo with four electric vehicle concepts and a bold new design language. While it’s great to see the company that gave the world the Leaf back in top form, the real game-changer might be Nissan’s all-solid-state battery (ASSB) development program.

Kazuhiro Doi, corporate vice president of Nissan’s research division, was on hand to talk about the emerging battery technology that could allow the company’s next generation of electric vehicles to take a quantum leap forward.

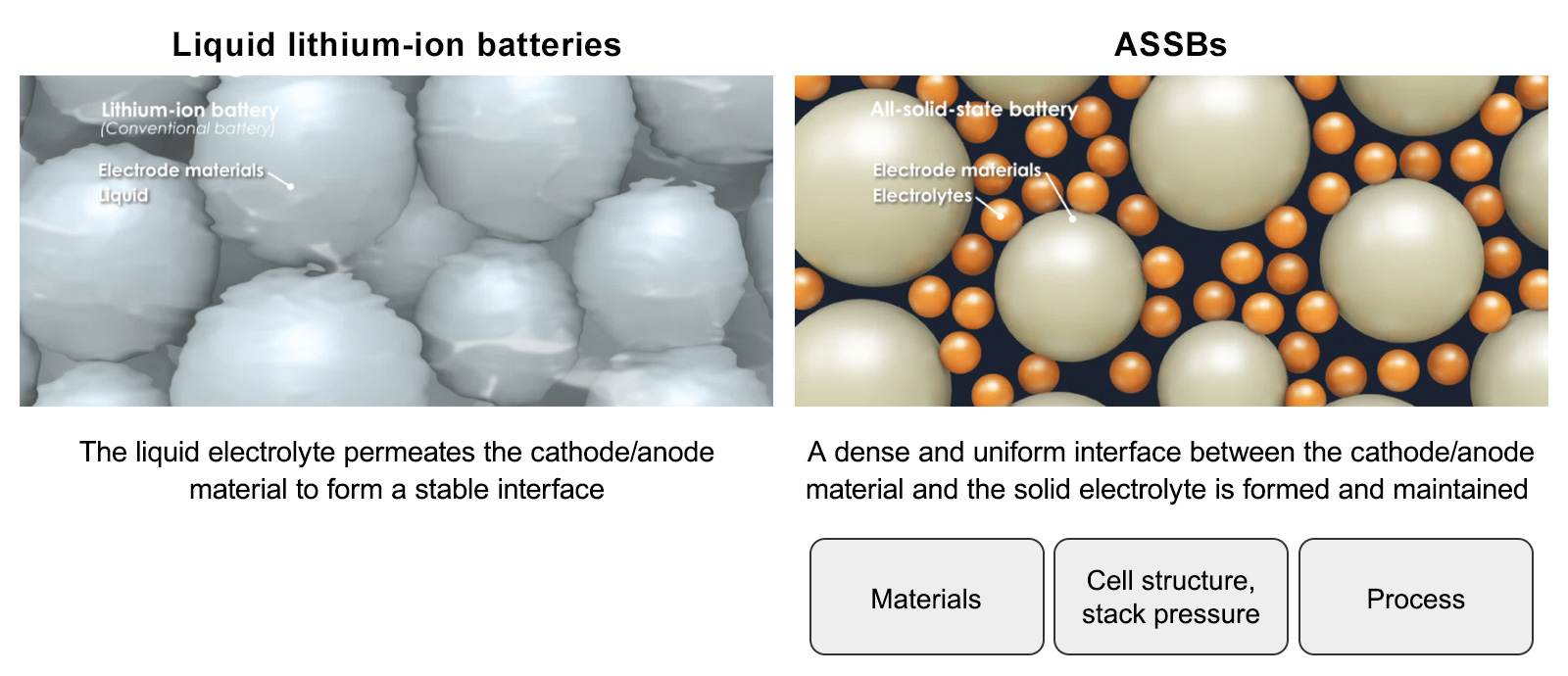

Announced roughly two years ago, ASSB technology could revolutionize EVs, giving them “almost double the energy density” of current batteries, according to Doi, with faster charging performance at a lower overall cost. Better living through chemistry.

Once realized, that higher power density opens up a wealth of potential options for Nissan product planners and engineers – and for “all car types” according to Doi. Getting twice as much energy from each cell could advantage large, heavy vehicles – like trucks or vans – by improving total range without having to increase the physical size of the pack. Nissan has also said these batteries could cut charging times to a third of what conventional ones offer.

In the other direction, sports cars or supercars – like the GT-R-aping Hyper Force concept –could use smaller, lighter battery packs to allow for better handling, braking, and acceleration.

But the design and packaging advantages don’t stop there. Doi also told me that ASSB technology offers a wider operational envelope in terms of temperature, too. When asked about the temperature sweet spot, Doi said that the batteries are happy from “room temperature to 100C.” As a result, the solid-state batteries don’t require any sort of dedicated cooling system, which means future Nissan products could ditch even more weight and mechanical complexity.

Doi and the team are moving forward according to Nissan’s previously announced schedule, too. A first pilot manufacturing plant is still on pace to begin operation next year, though I couldn’t get a comment on the facility’s production capacity. And the first production vehicle application of ASSB is still slated for 2028, with Doi saying, “I hope to make the next announcement very soon” when pressed on the details of said car.

here are still more than a few specifics to be worked out on the engineering front, notably balancing the construction of the cells for charging and discharging performance, as well as the lifecycle of the battery overall.

“First we have to fix the chemistry, then we can estimate the performance per cell,” Doi said. “To realize higher energy density the cathode has to be thicker… but then the charging is slower.” A magnesium sulfur-based technology could be the most affordable, and could “positively affect cycle life,” he said.

BMW, Volkswagen, and Toyota – to name a few – are also investing heavily in this field of solid-state research and production ramp-up but Doi is bullish about the Nissan effort, calling the company “in the top group” of this EV arms race.

It could use the boost. Despite success with the Leaf and launching the new Ariya crossover, Nissan is sometimes accused of losing an early lead it once had alongside competitors like Tesla. With automakers from China, Korea, and even the United States moving fast on EV rollouts, Nissan has no time to waste.

The company is already showing early signs of progress. Last month, Nissan announced that every new car launched in Europe would be an EV and that it would complete a fully electric transition in that region by 2030. “The world needs to move on from ICE,” CEO Makoto Uchida said at the time. But certainly, other automakers are racing in that direction too.

Whatever the outcome of that competition, it seems like solid-state batteries in general, and possibly even Nissan ASSB tech specifically, are poised to make EV shoppers the winners, very soon.